About Oems

Wiki Article

About Manufacturing Industries

Table of ContentsThe Ultimate Guide To Hon Hai PrecisionSome Of OemSome Known Details About Mfg Things about ManufacturingThe Best Strategy To Use For Additive Manufacturing

Then, the mould closes as well as the procedure repeats. Pre-moulded or machined components can be placed right into the dental caries while the mould is open, permitting the product injected in the following cycle to develop and also strengthen around them. This process is called Insert moulding and also permits solitary parts to contain several materials.

Many polymers, occasionally referred to as materials, may be made use of, including all thermoplastics, some thermosets, and also some elastomers.

Readily available materials include alloys or blends of previously established products, so item designers can select the product with the ideal collection of residential or commercial properties from a large option. Major requirements for choice of a product are the strength and function needed for the last component, along with the cost, however likewise each material has various criteria for moulding that need to be taken right into account.: 6 Various other considerations when selecting a shot moulding material consist of flexural modulus of flexibility, or the level to which a material can be bent without damage, along with warm deflection and also water absorption.

Some Known Incorrect Statements About Manufacturing

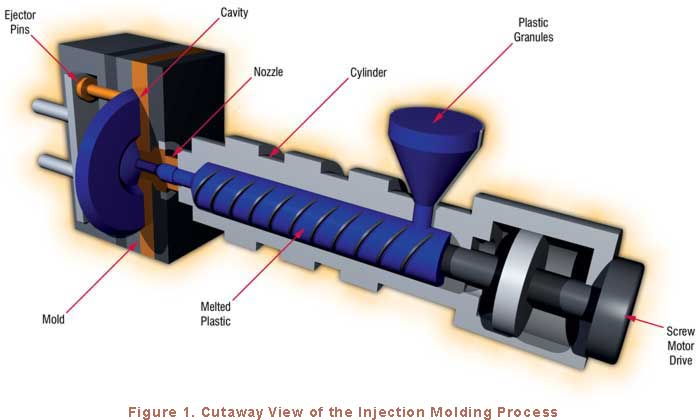

Applications consist of buckles for securing and also disconnecting outdoor-equipment webbing. Injection moulding makers are composed of a material hopper, a shot ram or screw-type bettor, and a home heating unit.: 240 Also understood as platens, they hold the moulds in which the components are formed. Presses are ranked by tonnage, which reveals the quantity of clamping force that the equipment can put in.

Mould or pass away are the common terms made use of to explain the tool made use of to produce plastic components in moulding. Given that moulds have been pricey to produce, they were typically only made use of in automation where thousands of components were being produced. Common moulds are created from hardened steel, pre-hardened steel, aluminium, and/or beryllium-copper alloy.: 176 The selection of material to construct a mould from is largely one of business economics; in general, steel moulds set you back more to build, however their longer lifespan offsets the greater initial price over a greater number of components made prior to breaking.

Some Known Factual Statements About Lean Production

Injection moulding die with side draws "A" side use this link of crave 25% glass-filled acetal with 2 side pulls. Close of removable insert in "A" side. "B" side of die with side pull actuators. Mould layout [modify] Standard two plates tooling core and also cavity are inserts in a mould base "household mould" of 5 different parts The mould contains 2 main components, the shot mould (A plate) and the ejector mould (B plate).Plastic resin gets in the mould through a or entrance in the injection mould; the sprue bushing is to seal tightly versus the nozzle of the shot barrel of the moulding equipment as well as to permit liquified plastic to stream from the barrel into the mould, likewise understood as the cavity.: 141 The sprue bushing routes the liquified plastic to the tooth cavity photos through networks that are machined right into the faces of the An as well as B plates.

(A) Sprue, (B)&(C)jogger and (D)gates in real shot moulding item for toys The quantity of resin called for to fill up the sprue, jogger as well as cavities of a mould consists of a "shot". Trapped air in the mould can run away with air vents that are ground right into the parting line of the mould, or around ejector pins as well as slides that are somewhat smaller sized than the openings keeping them.

The air can also become so pressed that it fires up as well as burns the surrounding plastic material.: 147 To enable removal of the moulded part from the mould, the mould attributes should not overhang one an additional in the direction that the mould opens up, unless components of the mould are developed to move from between such overhangs when the mould opens using parts called Lifters.

Hon Hai Precision Things To Know Before You Get This

The coolant takes in heat from the mould (which has absorbed warmth from the warm plastic) and maintains the mould at a correct temperature level to strengthen the plastic at the most reliable rate.: 86 To reduce upkeep as well as venting, cavities and also cores are split into items, find out called inserts, as well as sub-assemblies, also called inserts, obstructs, or chase blocks.Much more complicated parts are formed making use of a lot more complicated moulds. These may have areas called slides, that step right into a cavity vertical to the draw instructions, to develop looming part features. When the mould is opened up, the slides are pulled away from the plastic component by utilizing stationary "angle pins" on the fixed mould half. hon hai precision.

The component is then ejected and also the mould closes. The closing activity of the mould causes the slides to relocate forward along the angle pins.: 268 A mould can look at this now create several duplicates of the very same parts in a single "shot". The variety of "perceptions" in the mould of that part is frequently inaccurately referred to as cavitation.

Sometimes, multiple tooth cavity tooling moulds a collection of different parts in the exact same device. Some toolmakers call these moulds family moulds, as all the components are relatede. g., plastic model kits.: 114 Some moulds permit previously molded components to be returned to enable a brand-new plastic layer to form around the first component.

How Hon Hai Precision can Save You Time, Stress, and Money.

This system can permit production of one-piece tires and also wheels. Two-shot or multi-shot moulds are developed to "overmould" within a single moulding cycle and also must be refined on specialized injection moulding machines with 2 or even more shot systems. This process is in fact an injection moulding process performed two times as well as for that reason has a much smaller sized margin of mistake.The 2nd material, a different colour, is injection-moulded right into those areas. Pushbuttons and tricks, for circumstances, made by this process have markings that can not subside, and also stay clear with hefty use.: 174 Mould storage [edit] Producers most likely to terrific lengths to secure customized moulds as a result of their high average prices.

Report this wiki page